SST was founded to address the opportunity and need for advanced ceramics coatings in a variety of applications, as well as the need for fast, cost-effective methods for development of such coatings.

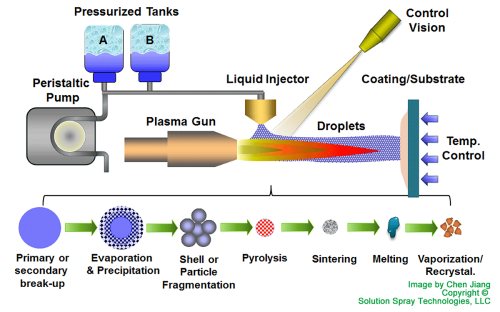

Our coatings, produced through unique plasma spray processes, are better because they offer a combination of unique microstructure/properties and low cost that is difficult to achieve with any competing ceramic coating/membrane manufacturing process.

With over a combined 70 years of ceramic coating development experience, our team has a proven track record of success for developing novel coatings for demanding applications. Our team can deliver high quality solutions that meet your project objectives, quickly and effectively.